1. Industrial Dust & Its Impact

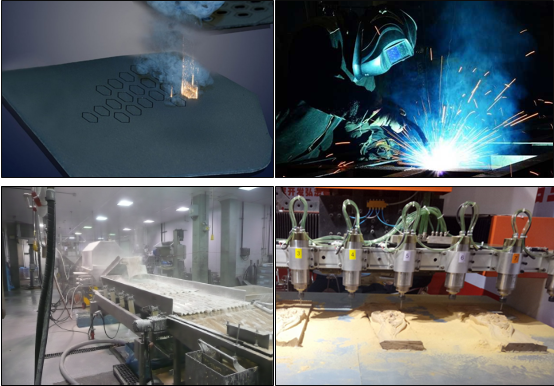

Industrial processes such as cutting, welding, grinding, and mixing in manufacturing and processing industries usually generate tremendous amount of industrial dust. The type and quantity of industrial dust depend on the industry and manufacturing process. For instance, during laser or plasma cutting and welding processes, tiny hazardous particles are generated in the form of fumes or smoke.

Dust in the industrial settings presents a variety of hazards with toxicity and explosion as the most prevalent. Industrial dust consists of tiny and solid particles (size from 1 µm up to around 100 µm) either floating in the air or sitting still on the surface of the object. As these particles are light and often invisible to the naked eye, they are not considered as an obvious harm to worker’s health.

Additionally, the dust not only put employee’s health at risk, but also accumulate and pose the risks of combustion or fire. In order to mitigate these hazards associated with dust, it is necessary to have good ventilation and customized fume and dust extraction systems to ensure a safer work environment.

2. Dust Collection System

An industrial dust collection system is a type of equipment used in industrial or commercial settings to control air pollution and to meet safety requirements of workplace. An effective dust collection system removes potentially harmful dust and fumes from manufacturing process or the air in the surroundings. Dust collectors can be classified into four main types:

- Filter cartridge dust collector

- Wet scrubbers

- Inertial separators

- Electrostatic precipitators

- Unit collectors

Each of these industrial dust collector is specially designed for a particular use. The type of dust differ by industry; therefore, industrial dust collectors are designed for the extraction method needed by each industry.

Most industrial dust collectors come with ducting that is connected to the inlet of a collector, a filter unit to filter the dirty air, a blower system to create airflow, a cleaning system for the filters, and a discharge system to collect particles. All of these parts may vary slightly depending on the application.

3. Benefits of Industrial Dust Collectors

Industrial dust collector has wide range of benefits. Some of them are briefly described below.

3.1. Improve Air Quality

Controlling dust in a manufacturing or production facility is an effective way to improve air quality. The industrial dust collection system captures the airborne dust and provides air with improved quality. Besides safeguarding the health of employees, improved air quality increases worker productivity and brings other benefits as well.

3.2. Enhance Health and Safety Standards

When the air containing dust and hazardous particles enters the lungs, it can cause serious health issues. An industrial dust collector helps to provide clean air, improve the air quality of the workspace, and traps harmful materials before they are exposed to the outer environment. Capturing dust from their source avoids workers’ exposure to airborne contaminants and keeps dust from traveling throughout the facility.

3.3. Increase Productivity

A study about the impact of indoor air pollution on worker productivity in the United States showed that a 4.2% improvement in productivity when air pollution was reduced by 10 ppb (parts per billion). It was observed that poor indoor air quality can waste six workdays per year for every ten employees. Furthermore, installing an industrial dust collector will allow the machinery to work at optimal performance.

3.4. Meet Compliance Standards

Numerous laws and regulations exist regarding workplace safety. Some of these regulations are related to environmental protection and the quality of the air such as OSHA. Poor air quality can cost heavy fines and bring potential hazards that can damage the factory or affect the health of employees. A proper industrial dust collection system can help to comply with governmental regulations as well as keep everyone safe in the building.

3.5. Environmental Protection

Installation of a proper industrial dust collection system ensures a safer and greener environment. It collects the harmful particles from the work environment and cuts its way to outside, reaching the goal of environmental protection.

4. Conclusion

The industrial dust collectors are widely used in the manufacturing industries to ensure the environmental safety and product quality. Since a large amount of harmful dust and fumes are produced during various manufacturing processes, it is inevitable to choose a reliable industrial dust collector.

Villo Vacuum, the leading industrial dust collector manufacturer, provides comprehensive solutions to guarantee production safety, product quality and employee’s health during the production process.They propose the ideal solution by professionally modeling your facility to guarantee the performance.