Introduction

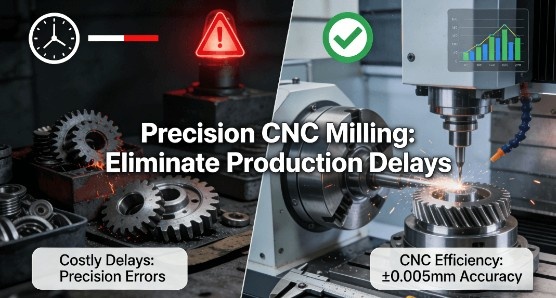

In modern manufacturing, industries face escalating demands for complex components in sectors like industrial equipment and automotive. Traditional machining methods often lead to precision shortcomings, production delays, and cost overruns. For instance, equipment manufacturers encounter rework during prototyping due to inadequate tolerance control. The root cause lies in a lack of understanding of advanced CNC milling principles and improper process selection, which exacerbates efficiency bottlenecks.

We study the main principles, working mode and application of CNC milling technology and combined with ISO 9001 and other lineaments. It provides a useful manual to manage the production flow. The rest of this paper is organised as follows: How CNC milling is the cornerstone of industrial innovation will be examined systematically.

What Is CNC Milling and How Does It Differ from Traditional Machining?

CNC milling is a subtractive manufacturing process in which rotary cutters are used to remove material, and is computer-controlled, which allows high precision and automation. Instead of the analogue process of manual milling, it uses digital models and toolpaths generated by software, giving it repeatable accuracy and less human error. In this part, we’ll discuss some major differences and benefits.

1. Definition and Computer Numerical Control Fundamentals

CNC milling functions by using G-code commands generated from CAD files, which allows for control over the spindle speed, feed rate and tool path, among other things. This automation eliminates the variability inherent with manual processes and results in consistency across mass production. The system incorporates feedback loops to make real-time adjustments at the micron-level to maintain micron-level dimensional accuracy. Reference to authoritative sources as for example Wikipedia, explains basic concepts in a non-commercial way and informs about its place in modern manufacturing technology. Using digital twins, operators simulate processes to reduce errors in real machining.

2. Key Differences from Traditional Machining Methods

Conventional milling relies on the operator’s experience to set the parameters, which results in variable output and longer setup time. On the other hand, CNC milling is fully automated and can be run around the clock with little supervision. For instance, changing complex shapes can be done unattended, saving on labour costs and increasing output. This transition highlights the technological change in manufacturing in which data-driven tools supplant manual operations. Research indicates that CNC decreases the setup time by as much as half that of the traditional method, making it suitable for mass production.

3. Benefits in Precision and Efficiency

The adoption of CNC milling brings superior accuracy, with tolerances achievable within microns. It also supports rapid prototyping by streamlining design iterations. Compared to conventional methods, CNC reduces scrap rates by 20-30%, as documented in industry studies. Additionally, it enables energy-efficient operations through optimized toolpaths, lowering overall production costs. For a more comprehensive principle analysis, readers can refer to this CNC milling guide.

What Are the Core Principles Behind High-Precision CNC Milling?

High-precision CNC milling lies on the solid technical foundation of geometric dimensioning and tolerancing (GD&T), multi-axis machine kinematics, and toolpath optimization. These components help make certain parts conform to tight tolerances, especially when used in critical industries.

1. Geometric Dimensioning and Tolerancing (GD&T) Standards

GD&T(as per ASME Y14.5) prescribes dimensional controls for orientation and form keyword features such as flatness and concentricity. Observance of these standards reduces the chances of errors in interpretation and also the parts’ fit to each other in the assembly. For example, ISO 9001 certification recognises systematic rigour in controls and builds trust without any branding. Applying standard GD&T practices, the company can help avoid more than 15% rework of parts and assemblies by making design intent more understandable between groups. This method is a must-have for industries like aerospace, where micro-level tolerances are a must-have.”

2. Multi-Axis Kinematics and Toolpath Strategies

Multi-axis systems (such as 5-axis milling) allow for dynamic tool orientation, enabling the tool to be orientated along the workpiece at the best possible angle. This cuts down on setups in both the tool and part and, more importantly, keeps a consistent datum reference line , which is huge when working with complex parts. Sophisticated CAM software produces collision-free tool paths, which improve surface finish and shorten machining time by as much as 25 per cent. By integrating kinematic models, continuous motion can be generated, reducing vibrations and tool wear. Real-time simulations provide additional path validation before execution , which can save thousands of dollars in avoidable mistakes.

3. Quality Assurance through Metrology Integration

Probing and CMMs over the machining process can be used to provide real-time compensation for tool wear. This closed-loop process, which is executed in accordance with standards such as ISO 9001, guarantees the tolerance of ±0.01 mm. Such an integration shows how the principles of precision can translate into real quality increases, such as less inspection time and a higher first-pass yield. When metrology is embedded directly into workflows, manufacturers gain traceability and the ability to meet regulatory demands.

How Do Different Types of CNC Milling Operations Address Specific Manufacturing Challenges?

CNC milling operations vary from 3-axis to multi-axis setups, each tackling unique challenges like thin-walled parts or deep cavities. This diversity allows manufacturers to select methods based on application needs.

- 3-Axis Milling for Simplicity and Affordability:3-axis milling is applicable to prismatic parts with linear features and offers a high-productivity, low-cost solution for mass production. The problem is that undercuts are not accessible with limited tool access, so you end up doing multiple setups. This can accumulate error, which in complex situations means you need advanced options. It continues to be widely used for prototyping and small quantities because of its simplicity and rapid set-up time, despite its limitations. Some precision problems can be remedied by proper fixture design, so the machine is really not a bad choice if you just want to get your feet wet.

- 5-Axis Milling of Complex Components: 5-axis milling allows the machining of free-form surfaces in a single setup, decreasing the number of re-handling by 30~40%. It solves the problem of, for example, tool collisions inside deep pockets and allows the processing of parts such as impellers without interruption. This functionality is critically important in fields that require high complexity and high speed , such as in medical device manufacturing. Simultaneous motion on multiple axes results in a more consistent removal of material, leading to stronger parts with better surface finish. The case studies demonstrate that 5-axis systems can reduce lead times by up to half compared to conventional techniques.

- Mill-Turn Manufacturing: Mill-turn centres are a combination of milling and turning centres, used for producing the entire rotational part. They may reduce lead times by as much as 50 per cent for items such as engine parts by eliminating secondary operations. It’s just one example of how hybrid techniques are breaking through the silos of traditional workflows. Combining processes enables manufacturers to increase the precision of their work and decrease the chances of errors in handling materials. These systems are ideal, especially for complex assemblies where concentricity and alignment are paramount.

What Are the Key Applications of CNC Milling in Industrial Equipment and Automotive Sectors?

CNC milling is pivotal in manufacturing high-performance parts for industrial machinery and vehicles. Its applications range from prototyping to full-scale production, driven by precision and compliance needs.

1. Industrial Equipment Components

In machines such as robots, CNC milling creates load-bearing parts with tight tolerances. For instance, armadillos need lightweight, yet strong arm segments that can be manufactured with optimised toolpaths. This brings und er the harsh environment robustness with reliability backed up by the curves like ISO9001. Application can also be found in the conveyors and hydraulics, with the same requirement of being wear resistant to ensure long life. Using high-strength alloys, the producers can improve the lifecycle of the components, reducing maintenance fees.

2. Automotive Sector Innovations

Automotive applications: engine blocks and transmission components for which IATF 16949 is a requirement. CNC milling allows for faster development of electric vehicle parts. Case studies demonstrate risk mitigation, such as thermal deformation of a brake system under braking. The technology enhances lightweighting by removing material accurately and enabling better fuel economy. As EVs develop, so does CNC milling with new materials such as carbon fibre composites and adaptations to the whole industry.

3. Custom Solutions for Emerging Needs

With the changing of industries, CNC milling now caters to specialised requests, for example, medical device housings or aerospace fittings. Services themselves can be customised to address particular problems, allowing for more flexibility in the quality of the service provided. For example, manufacturing on demand enables customers to produce end products with fast turnaround for small batches. This adaptability has made CNC milling a popular option for burgeoning industries such as renewable energy, where imprecision parts are vital for performance.

How Can Manufacturers Optimize Costs and Lead Times with Precision CNC Milling?

Cost optimization in CNC milling involves strategic planning in design for manufacturability (DFM), batch scheduling, and parameter settings. These steps reduce waste and accelerate time-to-market.

- Principles of Design for Manufacturability (DFM) DFM can make parts less complex by reducing the number of machining operations, leading to a reduction of material costs in the range of 15% to 20%. When manufacturers collaborate early with engineers to receive finalized designs, they are able to produce without wasting potential resources, avoiding redesign work, as approved by ISO 9001 quality management systems. Some tactics are standardizing features (such as hole sizes and radii) to reduce tool changes. This feed-forward methodology prevents production delays and makes large volume production more scalable.

- Carrying out DFM evaluations in the design stages reduces the prototyping costs by as much as 30%.Scheduling in and Efficiency of Batch Production: Similar parts are batched together, leading to a better utilization of the tool changes and machine, and a reduction of inactive time up to 35%. Demand is predicted by intelligent scheduling software so that production is synchronised with delivery deadlines to avoid delays. Just-in-time manufacturing processes help keep inventory costs down and allow for less storage. Using production information, manufacturers can track down bottlenecks and establish more efficient workflows. This best-practice goes a long way to guaranteeing on time delivery without compromising quality.

- Sustainability through Adaptive Parameter Control: Tool life and energy consumption can be improved via real-time-based cutting parameter modification. This adaptive scheme enables green manufacturing by reducing operating costs without sacrificing the quality of output. For instance, when you optimize use of coolant, you reduce your environmental footprint and increase employee safety. Adaptive control has been shown to save energy by about 15-20% making production greener [11]. By integrating IoT sensors, continuous monitoring and control can be achieved, further improving the efficiency of the system.

What Future Trends in CNC Milling Will Shape Manufacturing Technology?

Emerging trends like AI-driven predictive maintenance and IoT integration are set to revolutionize CNC milling, making it smarter and more sustainable.

1. AI and Predictive Maintenance

AI processes machine data to predict failures, which results in a 20% decreased downtime. This predictive maintenance is in line with Industry 4.0 objectives for OEE improvement. Using machine learning models, they are able to predict tool wear and replace tools automatically. This development reduces unplanned downtime and increases the life of the machinery. We will have fully autonomous machining cells ; and as AI advances, there will be no floor for production to revolutionise, Rafael said.

2. Sustainable Manufacturing Practices

Regulatory guidelines from agencies such as the EPA advocate for energy-efficient machining that includes reduced coolant usage, recycled materials and compressed air. These methodologies reduce carbon footprints and retain accuracy. Advances such as dry machining conserve fluid, and biodegradable coolants used in the machining environment promote sustainability. Part makers are implementing circular economy strategies by recycling metal scraps in support of global sustainability ambitions. This change is good not only for reducing costs but also for improving corporate social responsibility.

3. Digital Twin Technology

Digital twins simulate machining processes, allowing virtual testing before production. This reduces trial costs and accelerates innovation, CNC milling services as a driver of future-ready manufacturing. By creating virtual replicas, engineers can optimize parameters and detect issues early. This technology supports remote monitoring and collaboration, especially in global supply chains. As digital twins become more accessible, they will democratize high-precision manufacturing for smaller enterprises.

Conclusion

CNC milling, through its integration of precision principles and diverse operations, has become a core enabler for industrial equipment manufacturing. It effectively mitigates delays and cost risks by ensuring accuracy and efficiency. As technology advances, its role will expand, underpinning smart manufacturing initiatives.

FAQs

Q: What is the typical tolerance achievable with precision CNC milling?

A: Precision CNC milling can achieve tolerances as tight as ±0.005 mm, depending on material and machine capabilities. Adherence to standards like ASME Y14.5 ensures consistency in critical applications, reducing rework and enhancing product lifecycle.

Q: How does CNC milling compare to 3D printing for rapid prototyping?

A: While 3D printing excels in speed for complex geometries, CNC milling offers superior material strength and surface finish. Milling is ideal for functional prototypes requiring durability, whereas printing suits form validation, with choice depending on load-bearing needs.

Q: What materials are most suitable for high-precision CNC milling?

A: Metals like aluminum and titanium provide excellent machinability for high-strength parts, while engineering plastics like PEEK offer chemical resistance. Selection should align with application requirements, guided by ISO standards for quality assurance.

Q: Can CNC milling handle complex geometries like undercuts or thin walls?

A: Yes, multi-axis CNC milling machines specialize in complex features such as undercuts and thin-walled structures. Advanced toolpath programming maintains integrity even on delicate designs, minimizing distortion risks.

Q: How do certifications like ISO 9001 impact CNC milling service quality?

A: Certifications like ISO 9001 enforce rigorous process controls, ensuring consistent quality from design to delivery. This systemic approach minimizes defects and compliance issues, particularly in regulated industries.

Author Bio

The author is a precision manufacturing expert at LS Manufacturing, a company that helps engineers and researchers solve complex part challenges in aerospace, medical, and automotive industries. With certifications such as ISO 14001 and AS9100D, the team ensures high-quality, sustainable solutions through advanced technologies. For more insights, contact them today for a free, no-obligation project review and DFM analysis to turn your concept into a cost-effective reality.