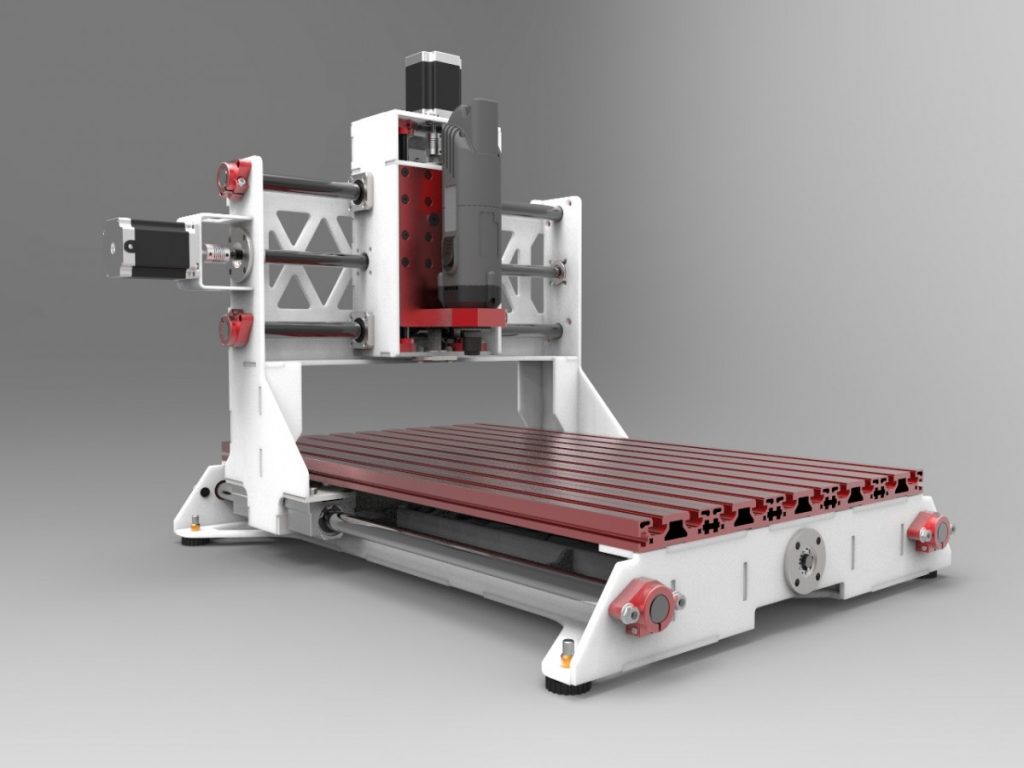

CNC router machine is the most advanced technology used by the industrialists around the globe to manufacture metal products with precision and speed. It is available in different shapes and sizes and is more reliable and cost effective than the machining tools. These machines have made the work easy and less time consuming for every machine operator and business professional in this field. These CNC routers can work on diverse kinds of metals and plastics. The router machine has enabled the manufacturing industries to provide consistent high quality work to the products.

Elephant CNC router is a CNC router machine which uses CNC technology to operate the functions by sequentially cutting the pieces as per the pre-established instructions. You can easily download fdf blueprint file for creating the CNC machine for cutting on CNC routers. In fact, it is one of the popular toys that children love and enjoy for hundreds of years now. Children play with this amazing toy horse for hundreds of years now.

Send Inquiry from Customer with CNC Router Machines

You can also send inquiry from customer with CNC router machines. The customer may buy a product of his choice and request for any modification in its characteristics. However, before sending an inquiry, make sure that all the requirements of the customer are met. It should include the specification of the product, the measurement, material type, cut list etc.

The standard operating procedures should be followed and accurate documentation should be maintained for regular maintenance. The other procedure is to send an inquiry about the specifications of CNC router to the supplier.

When you start the CNC router operation, firstly the spindle motor will be placed and aligned. After the proper positioning accuracy, the machine will be aligned and the cutters will be switched on. The first cuts will be made, normally in a straight line. This is referred to as the drawing phase. The CNC router tool changes gears at these phases to give you better positioning accuracy.

Process

Then, the process continues with the process of data transfer from the computer to the CNC router. The tool change machine will operate at full speed when the command for switching off comes from the computer. Then, the cutting process starts with the first cut made parallel to the surface of the material being cut. Thereafter, the process goes on with the second cut being done in the same direction but slightly off to the left and so forth till the end of the material being cut.

When any of the above cuts comes out in the wrong direction, the fault will be detected and the control box will automatically stop the machine. The process is normally completed in seconds and if there is any problem related to tool change machine, the first inspection method used by the machine tool will be used. However, if the problem persists despite of switching off and on the machine a manual command will be given to the machine.

Detecting the Fault

After detecting the fault, a series of tests will be performed to find out the root cause of the fault. If it is due to the mechanical drive, then the drive mechanism will be checked and lubricated to increase the life of the drive. If it is due to the electrical system, the CNC routers machine motor will be checked and its RPM’s will be manually increased or decreased depending on its condition. It may also be required to check the timing systems of the CNC automatic tool changer and other components like the flywheel etc… These things are done periodically, say once every month, to ensure that the machine continues to work effectively even after minor problems.

It is advisable to carry out the CNC fault diagnosis test program in the presence of an authorized person. Such an expert would be an employee of a CNC testing center who has undergone several years of training. In order to prevent mishaps from happening, the machine tools have been designed to automatically stop the process if a fault is detected during the process.

It is very important to take the machine tool parts, like the spindle, gear sets, drill bits, and lathe head as close to the manufacturer’s specifications as possible. This will help avoid factory defects. The test program offered by the manufacturers keeps your CNC routers functioning like the best they can be so that it is ready to be used confidently.

DXTECH LASER

If you’re looking for a way to get your hands on a good laser cut lamp for your business or personal use, then the best thing to do is look online for a sale on the DXTECH LASER. The machines are well-known around the world and are known to offer the highest level of performance and quality in their products. When you are looking to buy one of these machines, it is important to understand exactly how they work. This is because the technology used in a typical DXTech machine allows it to cut through many types of metals with the greatest of ease.

One of the most common applications for DXTech laser cutters is engraving. Engraving can range from using the machine to cut letters into letters and logos to etching. Using the DXTech laser cutter in this situation can help you make sure that your logo or letters stands out and gets noticed. In some cases, the engraving can be so intricate that it may not be possible to etch the design without a professional doing it for you – and this is where the benefits of the DXTech machine come in.