Mechanical seals are vital in pumps, compressors, and other rotating equipment, preventing leaks while ensuring reliable operation. Their performance largely depends on the seal face material, which affects wear resistance, temperature tolerance, and chemical durability. This article explores common seal face materials, their pros and cons, and how to choose the right one for your application.

Why Seal Face Material Matters

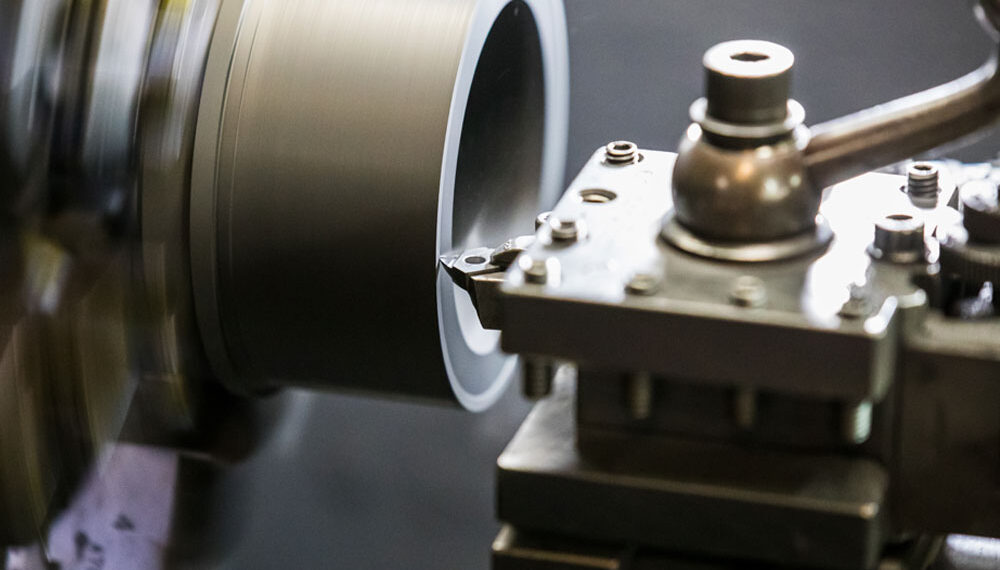

Seal faces are in constant contact, sliding against each other at high speeds and under varying pressures. This makes them prone to frictional heat, wear, and corrosion. A carefully chosen material ensures:

- Durability – extending seal life by resisting wear

- Compatibility – with process fluids, preventing chemical degradation

- Thermal stability – handling the heat generated by friction

- Efficiency – reducing energy losses due to friction

The wrong choice can result in leaks, costly downtime, and equipment damage. That’s why industries—from petrochemicals to food processing—invest in selecting the right seal face material for each unique process.

Common Seal Face Materials

- Carbon

Carbon is one of the most widely used seal face materials. It offers excellent chemical resistance, self-lubricating properties, and low friction, making it ideal for various applications. Carbon faces can run against harder materials like silicon carbide or tungsten carbide, providing a balance of durability and cost-effectiveness.

- Strengths: Low friction, chemical compatibility, resists thermal shock

- Limitations: It can be brittle and prone to wear in abrasive environments

- Applications: General industry, water pumps, chemical processing

- Silicon Carbide

Silicon carbide is a hard, durable, and corrosion-resistant material. It’s available in both reaction-bonded and sintered forms, each offering slightly different properties. Known for its excellent thermal conductivity, it efficiently dissipates friction-generated heat.

- Strengths: High hardness, low wear rate, excellent thermal performance

- Limitations: More expensive than carbon; brittle under impact.

- Applications: Abrasive slurries, high-temperature fluids, chemical industries

- Tungsten Carbide

Tungsten carbide is another tough material with outstanding resistance to wear and deformation. It’s often selected for demanding applications involving abrasive or high-pressure conditions. Its toughness makes it less brittle than silicon carbide.

- Strengths: High wear resistance, robust under mechanical stress

- Limitations: Heavier than alternatives, more costly

- Applications: Oil and gas, mining, slurry pumps, high-pressure systems

Ceramic

Ceramic seal faces, such as alumina oxide, offer excellent hardness and corrosion resistance. They are suitable for applications with less demanding mechanical loads but where chemical compatibility is important.

- Strengths: Corrosion resistance, hardness, and cost-effectiveness

- Limitations: Brittle, less effective under high thermal shock

- Applications: Light-duty chemical processes, food and beverage industries

- Polymer-Based Materials

Some applications use advanced polymers such as PTFE (Teflon) or engineered plastics as seal faces. These are chosen for their chemical inertness and ability to operate in environments where metals and ceramics might degrade.

- Strengths: Excellent chemical resistance, lightweight

- Limitations: Lower wear resistance compared to carbides

- Applications: Chemical handling, pharmaceutical, and food industries

Pairing Seal Face Materials

In practice, mechanical seals often use a pair of materials for the two opposing faces. A common pairing is carbon against a hard material like silicon carbide or tungsten carbide. This combination reduces friction while maintaining wear resistance. Using two hard faces together can benefit abrasive conditions, while two softer faces may work in non-abrasive, chemically aggressive environments.

Factors to Consider When Choosing Seal Face Materials

Selecting the right material isn’t just about durability; it’s about matching performance to the specific operating conditions. Here are key factors to evaluate:

- Process Fluid – Is it corrosive, abrasive, or prone to crystallization?

- Temperature Range – Can the material handle thermal expansion and shock?

- Pressure – Higher pressures require tougher materials to prevent deformation.

- Speed of Rotation – Faster speeds generate more frictional heat.

- Industry Standards – Some industries, like food or pharmaceuticals, require FDA-compliant or hygienic materials.

- Cost vs. Performance – Balancing upfront costs with long-term reliability.

Choose the Right Seal Face Material

Seal face innovations are advancing as industries seek greater efficiency and lower maintenance. Composite materials now combine toughness with self-lubrication, diamond-like coatings (DLCs) boost hardness and reduce friction, and eco-friendly options support sustainability. These improvements extend seal life, cut energy use, and lessen environmental impact.

Seal face materials are essential to equipment reliability, from carbon’s self-lubrication to tungsten carbide’s strength. The right choice depends on fluids, pressure, temperature, and industry needs. With advancing technologies, investing in the right seal face material safeguards against leaks, downtime, and costly repairs.