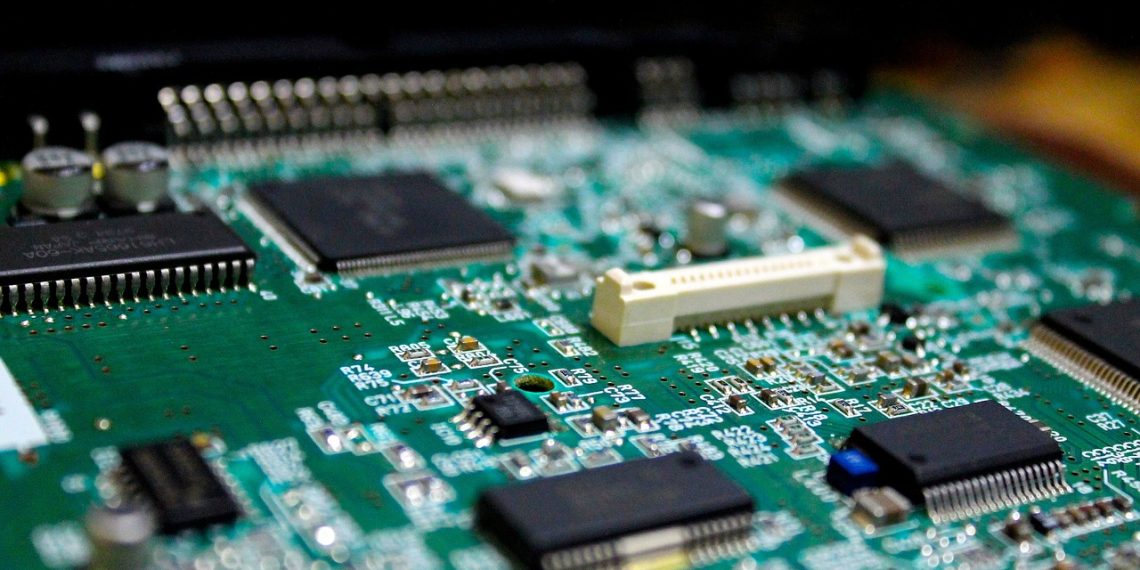

In the electronics industry, consistency and reliability are essential for producing high-quality products. IPC standards provide the guidelines manufacturers need to achieve uniformity and excellence in PCB production. These globally recognised standards cover everything from design and assembly to inspection and testing, helping manufacturers meet strict quality benchmarks. This article explains what IPC standards for PCB manufacturing are, highlights key standards relevant to PCB manufacturing, and examines how they contribute to better quality control.

What Are IPC Standards?

IPC standards are a set of guidelines developed by the Association of Connecting Electronics Industries, commonly known as IPC. These standards define best practices for designing, fabricating, and assembling PCBs, ensuring consistency across the industry.

By following IPC standards, manufacturers can maintain high levels of reliability, minimise defects, and improve the overall performance of their products. Adopting these standards is particularly valuable in sectors like aerospace, automotive, and medical technology, where quality is critical.

Key IPC Standards for PCB Manufacturing

Several IPC standards play an important role in guiding PCB manufacturing processes. Here are two of the most widely used:

IPC-A-600

Known as the “Acceptability of Printed Boards,” this standard provides detailed criteria for the visual inspection of PCBs. It includes guidance on acceptable surface conditions, copper thickness, and solder mask application, helping manufacturers identify and address defects during production.

IPC-6012

This standard outlines the requirements for rigid PCBs, including performance specifications and reliability criteria. It is particularly important for high-reliability applications, ensuring that the boards can withstand demanding operating conditions.

How IPC Standards Improve Quality Control

IPC standards play an integral role in improving quality control across the PCB manufacturing process.

- Consistency: By adhering to standardised guidelines, manufacturers can maintain uniformity across production, reducing variability and ensuring consistent quality in every batch.

- Reliability: IPC standards help identify potential issues early in the process, minimising defects and improving the long-term performance of PCBs.

- Customer Confidence: Compliance with IPC standards reassures customers that products are built to meet stringent quality and performance benchmarks, building trust and repeat business.

- Cost Efficiency: By promoting best practices and reducing waste caused by errors or rework, IPC standards help manufacturers save on costs while maintaining high-quality output.

IPC standards provide clear benchmarks for design, production, and inspection in PCB manufacturing. By following these guidelines, manufacturers can create reliable, consistent, and high-performing PCBs that meet the needs of industries requiring precision and durability. Whether it’s achieving uniformity or building trust with customers, adherence to IPC standards is an essential step for staying competitive in the electronics market.