I. Introduction

A. Brief explanation of connecting rods in an engine

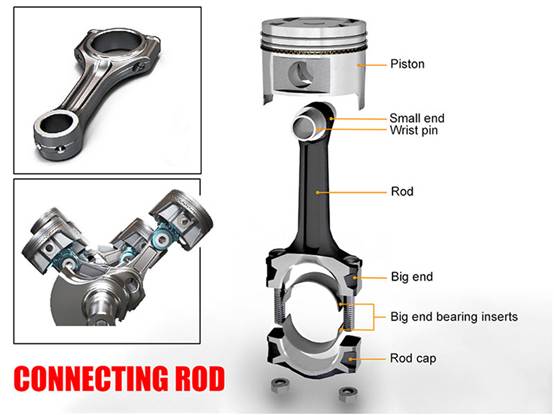

Connecting rods are essential components in an engine that connect the pistons to the crankshaft, transferring the linear motion of the pistons into rotational motion. They play a vital role in the engine’s overall performance and efficiency.

B. Importance of connecting rods in engine operation

The importance of connecting rods in engine operation cannot be overstated. They must withstand immense forces and pressures, ensuring smooth and efficient operation of the engine. Without properly functioning connecting rods, the engine’s performance, reliability, and longevity are compromised.

C. Overview of the issue of bent connecting rods

The issue of bent connecting rods is a serious concern for engine owners and mechanics alike. Bent connecting rods can result from various factors, such as mechanical stress, improper maintenance, or external factors like foreign object ingestion. When a connecting rod becomes bent, it can lead to engine knocking, misfiring, loss of power, and even catastrophic engine failure if not addressed promptly.

II. Common Causes of Bent Connecting Rods

A. Over-revving the engine

- Over-revving the engine occurs when the engine speed exceeds its recommended limits, putting excessive stress on the connecting rods.

- Examples of situations where over-revving can occur include aggressive driving, racing, and improperly shifting gears.

- To prevent over-revving, it is essential to follow the manufacturer’s recommended RPM limits and avoid excessive throttle input.

B. Lack of lubrication

- Proper lubrication is crucial for reducing friction and heat generation in the engine, protecting the connecting rods from excessive wear.

- Inadequate lubrication can lead to increased friction and heat buildup, resulting in accelerated wear and potential bending of the connecting rods.

- Regular oil changes and using high-quality lubricants are recommended to ensure adequate lubrication and prevent damage to the connecting rods.

C. Detonation or pre-ignition

- Detonation and pre-ignition can cause sudden, high-pressure combustion events in the engine, putting additional stress on the connecting rods.

- The increased pressure from these events can lead to bending or distortion of the connecting rods, affecting engine performance and reliability.

- Using higher octane fuel and avoiding excessive engine load are crucial steps to prevent detonation and pre-ignition events.

D. Inadequate fuel quality

- Poor quality fuel can lead to combustion issues, carbon buildup, and increased engine wear, potentially damaging the connecting rods.

- Using low-quality fuel can result in reduced engine performance, increased heat generation, and potential bending of the connecting rods.

- Opting for reputable fuel sources and using additives when necessary can help maintain fuel quality and protect the engine components.

E. Foreign object ingestion

- Foreign objects entering the engine through the intake system or other openings can cause physical damage or blockages to the connecting rods.

- The presence of foreign objects can disrupt the engine’s operation, leading to potential bending or misalignment of the connecting rods.

- Regularly inspecting the engine for foreign objects and keeping it clean can help prevent damage to the connecting rods and ensure smooth engine operation.

F. Improper torque on connecting rod bolts

- Proper torque specifications for connecting rod bolts are essential for maintaining structural integrity and preventing loosening or shearing of bolts.

- Under or over-torquing the connecting rod bolts can result in compromised stability and alignment of the rods, leading to potential bending.

- Checking and adjusting the torque on connecting rod bolts during maintenance procedures is recommended to prevent issues and ensure optimal engine performance.

III. Effects of Bent Connecting Rods

A. Engine knocking or misfiring

- Bent connecting rods can lead to irregular combustion within the engine, resulting in engine knocking or misfiring.

- These issues can create a rough running engine, reduced fuel efficiency, and potential damage to other engine components.

- Ignoring engine knocking or misfiring can worsen the condition of the connecting rods and lead to further engine problems.

B. Loss of power and performance

- Bent connecting rods can disrupt the smooth operation of the engine, causing a decrease in power output and overall performance.

- Engine responsiveness may be compromised, leading to slow acceleration, reduced top speed, and decreased efficiency.

- Addressing bent connecting rods promptly is crucial to restore optimal engine power and performance.

C. Potential for catastrophic engine failure

- If left unaddressed, bent connecting rods can escalate to catastrophic engine failure, causing severe damage to the engine block, pistons, and other vital components.

- The sudden failure of connecting rods can result in extensive repair costs, vehicle downtime, and even safety hazards if the engine malfunctions while driving.

- Regular maintenance and monitoring of connecting rods are essential to prevent catastrophic failures and ensure the longevity of the engine.

D. Increased risk of internal engine damage

- Bent connecting rods can cause increased stress and strain on other engine components, leading to potential internal damage.

- The misalignment caused by bent rods can result in wear on crankshaft bearings, pistons, and cylinder walls, accelerating overall engine wear.

- To prevent widespread internal engine damage, it is crucial to address bent connecting rods promptly and conduct thorough inspections to assess the extent of the damage.

IV. Prevention of Bent Connecting Rods

A. Regular maintenance and inspections

- Regular maintenance checks, including oil changes, filter replacements, and engine inspections, help identify potential issues with connecting rods early on.

- Inspecting connecting rods for signs of wear, damage, or misalignment can prevent further damage and ensure the longevity of the engine.

- Following the manufacturer’s recommended maintenance schedule and addressing any concerns promptly can help prevent bent connecting rods.

B. Using high-quality lubricants

- Utilizing high-quality lubricants designed for the specific engine type and usage can reduce friction, heat generation, and wear on connecting rods.

- Proper lubrication helps maintain optimal engine performance, protects connecting rods from excessive wear, and prolongs the lifespan of engine components.

- Choosing lubricants with the appropriate viscosity and additives can enhance engine protection and prevent issues like bent connecting rods.

C. Avoiding aggressive driving habits

- Aggressive driving, such as excessive speeding, rapid acceleration, and hard braking, can increase stress on connecting rods and other engine components.

- Gentle acceleration, smooth braking, and maintaining consistent speeds can reduce the strain on connecting rods and minimize the risk of bending.

- Practicing safe driving habits and avoiding unnecessary strain on the engine can help prevent damage to connecting rods and ensure optimal engine performance.

D. Ensuring proper torque specifications are followed

- Following manufacturer-recommended torque specifications for connecting rod bolts is crucial for maintaining structural integrity and alignment.

- Proper torque tools ensures the secure attachment of connecting rods, reducing the risk of loosening, shearing, or misalignment that can lead to bending.

- Using a torque wrench and checking the torque of connecting rod bolts during maintenance procedures can help prevent issues and ensure the stability of the rods.

E. Monitoring engine performance and addressing any unusual noises or vibrations

- Paying attention to changes in engine sound, performance, or vibrations can indicate potential issues with connecting rods or other engine components.

- Engine knocking, misfiring, or unusual noises can be signs of bent connecting rods or other mechanical problems that should be addressed promptly.

- Regularly monitoring engine performance, conducting diagnostic tests, and seeking professional assistance if any abnormalities are detected can help prevent damage to connecting rods and ensure the reliability of the engine.

V. Conclusion

A. Recap of the importance of connecting rods in engine operation

- Connecting rods play a vital role in the proper functioning and power delivery of the engine.

- They transmit the force of the pistons to the crankshaft, facilitating the movement of the engine and ensuring smooth operation.

- Maintaining the integrity and alignment of connecting rods is essential for optimal engine performance and longevity.

B. Emphasis on the need to prevent bent connecting rods through proper maintenance and care

- Preventing bent connecting rods through regular maintenance, inspections, and following recommended procedures is crucial for engine health.

- Proper lubrication, driving habits, torque specifications, and vigilance in monitoring engine performance are key preventative measures.

- Bent connecting rods can lead to significant engine damage, costly repairs, and safety hazards, highlighting the importance of proactive prevention.

C. Encouragement for engine owners to be vigilant and proactive in preserving the health of their engines

- Engine owners should prioritize regular maintenance, inspections, and addressing any signs of trouble promptly to prevent issues like bent connecting rods.

- Being proactive in caring for the engine, practicing safe driving habits, and using quality lubricants can enhance engine performance and longevity.

- By staying vigilant and proactive, engine owners can ensure the smooth operation, reliability, and longevity of their engines, ultimately saving time and money in the long run.