TDK’s MLCC Cross-Reference tool is a useful resource for finding capacitor replacements, if not somewhat limited by the amount of competitor MPNs available in the system. In the example linked above, TDK’s engineers recommend their “CGA” series as replacements for AVX’s “FLEXITERM®” series of X7R capacitors. This article will take a closer look at how these capacitor cross-references can be generated, independent of any manufacturer-specific tools, quickly validated, and safely integrated into existing board designs. First, we will look at the two series from a simple cross-reference perspective. We will make a more detailed analysis of performance at different operating points, and finally, an automated cross-reference tool will be introduced.

Comparing Datasheet Values of Ceramic Capacitors

The process of finding a correct replacement part for a ceramic capacitor starts with comparing the datasheet values. In this example, we will take a pair of capacitors, one from each series, and look at the electrical and mechanical parameters typically used when engineers create general part cross-references, like the ones seen in the TDK example at the top of the article.

We will examine the two capacitors today are the TDK CGA3E2X7R1H104K080AE (CGA Series) and the AVX 06035C104K4Z2A (FLEXITERM® Series). If the datasheet parameters are compared for these two products, it appears that they are the same. They share the same mechanical size/case code (0603), capacitance (100nF), voltage rating (50V), dielectric (X7R), and tolerance (10%). Also, both are automotive rated and feature soft terminations. A typical cross-reference ends here with the conclusion that the parts are perfectly compatible. We will take a more detailed approach in the next section and see if these two capacitors are indeed identical.

Operating Point Analysis of Ceramic Capacitors

A comparison of datasheet values is a good starting point for cross-referencing. Still, it does not answer one crucial question: How do these parts perform at the operating voltage and frequency at which they will be used? In the past, this type of analysis has been too time consuming or simply ignored since the functional point behavior of parts needed to be measured manually or (if you’re lucky) found on the manufacturer’s website. If these characteristic charts are available for each part, the two graphs must be compared by eye, challenging considering the different scales and measurement conditions used by other manufacturers.

Today, operating point analysis can be done simply, and for free, using the chart comparison tools at SourcingBot. Their engineers have collected and compared lab-measured data for ceramic capacitors and other passive components to be easily compared across datasheet values and operating points. If we search for our two capacitors, we can easily see the impedance and series resistance against frequency and the change in capacitance against frequency. This is where we can verify if our two capacitors will perform the same at our intended operating point.

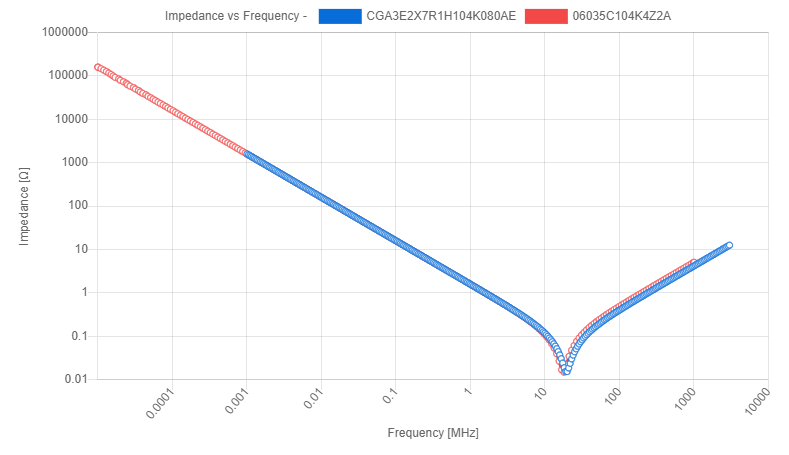

Here we can see the impedance behavior of the two capacitors at different frequencies. This chart tells us that the two capacitors have nearly identical self-resonant frequencies, which means that their operating frequency range is also the same.

Here the capacitance against voltage behavior is displayed. It can be seen that the TDK part retains more capacitance across the entire rated voltage range. At the rated voltage, the TDK part has 40% more capacitance than the AVX part! This difference may be critical in decoupling or filter applications. Depending on the operating point at which the capacitor will be used, these characteristic charts can inform you whether the two parts will perform the required specifications.

Automating the Cross-Referencing Process with SourcingBot

In this article, we have seen that all cross-references are not made equal. At specific operating points, the two capacitors do not perform the same, meaning that more in-depth analysis is required to guarantee compatibility. The engineers have automated this entire process at SourcingBot to speed up your product development and strengthen your supply chain. Their website automatically performs the first step of cross-referencing, the datasheet comparison, and presents a list of the most similar parts. It is simple to compare the performance at your operating point within the comparison table with their “Click to Compare” button.

To try the SourcingBot cross-referencing and comparison tools, visit their website at sourcingbot.com and start finding parts!