In the always-changing world of making things, the arrival of CNC machines, made by machine manufacturer, has been a big deal, especially in making furniture. This article talks about how Computer Numerical Control (CNC) machining, done by these machine makers, has a really important impact on the industry. It’s like a super tool, but more than that, it’s like the spark that’s changing how we think about, design, and make furniture. It’s important to know that CNC machines, created by machine manufacturers, are not just tools; they’re kind of like the superheroes that are shaking things up in the furniture world.

The Rise of CNC Machining in Furniture Production

The rise of CNC machining in furniture production is a testament to its ability to meet the evolving demands of consumers and craftsmen alike. As customization becomes a focal point in furniture design, CNC machining stands as the vanguard, offering the means to turn unique visions into tangible masterpieces.

Increased Demand for Customization

In the intricate world of furniture design, the contemporary consumer is propelled by a profound desire for unparalleled uniqueness. This surge in demand for customized furniture represents a paradigm shift, where each piece is a reflection of individual taste and style. CNC machining, rising to meet this challenge, emerges not only as a solution but as a creative enabler, providing the means to seamlessly translate diverse individual preferences into tangible, bespoke pieces that transcend the ordinary.

Advantages of CNC Machining

Diving into how CNC machines work shows that they’re good at smartly making furniture. They don’t just help with making unique pieces; they’re like superheroes for accuracy, making every cut and design super precise. And that’s not all—they also help to reduce waste, which is good for the environment, and they speed up how fast furniture gets made. This awesome combo not only meets what people want but also changes how furniture is made in a big way.

Overview of CNC Machining Technology

CNC machining technology is like the brains and brawn of modern furniture creation. It involves using computers to control machines with incredible precision, transforming digital designs into tangible pieces. This fusion of computer intelligence and mechanical prowess is the secret behind the accuracy and efficiency that define CNC machining.

Computer Numerical Control (CNC)

Computer Numerical Control (CNC) lies at the heart of modern manufacturing, blending computer programming and mechanical precision. This technological marvel empowers machines to execute intricate tasks with unmatched accuracy. Imagine it as a symphony conductor, harmonizing the dance of cutting and carving raw materials into finely crafted furniture. The CNC system translates digital designs into a precise language, guiding the machinery with a series of meticulous instructions. In this elegant fusion of computer intelligence and mechanical finesse, CNC machining emerges as the orchestrator of manufacturing precision.

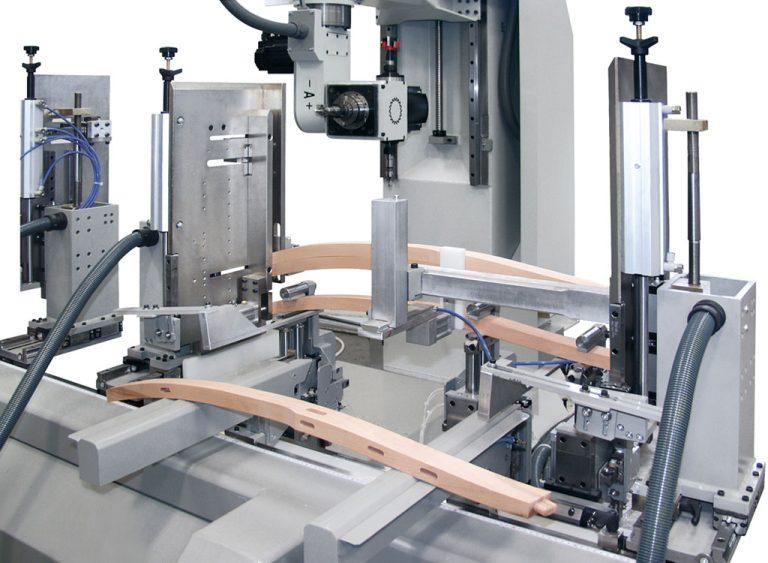

Types of CNC Machines

CNC machines come in different types, each with its own special job. Then there are CNC mills, like metalworking superheroes, shaping metal with super precision. These machines are like creative tools for craftsmen, helping them easily switch between working with wood and metal. It’s like having a bunch of skilled helpers, making it super easy for craftsmen to create all sorts of amazing furniture. CNC machines are like the cool artists of the furniture world!

Working Principle of CNC Machining

Understanding how CNC machining works involves recognizing the partnership between digital precision and mechanical strength. The core of this process lies in the computerized control system, a sophisticated conductor guiding the machine’s movements. Through a series of precise instructions, the CNC system ensures that each cut, carve, or shaping operation is executed with meticulous accuracy. This systematic approach not only enhances efficiency but also guarantees the consistent production of intricate and precisely crafted furniture pieces.

Design Flexibility and Versatility

CNC machining revolutionizes furniture production by creating customized pieces for homes and businesses with unparalleled precision. It plays a crucial role in architectural woodworking and interior design, bringing intricate detailing to life. Additionally, the versatility of CNC machines extends to crafting specialty furniture, offering a wide range of possibilities for unique applications.

From Sketches to Digital Designs

The journey from concept to creation begins with translating hand-drawn sketches into digital designs. CNC machining seamlessly facilitates this transition, providing craftsmen with a virtual canvas to visualize and refine their ideas. By working with digital designs, craftsmen can experiment with various elements, ensuring that every detail is perfected before the actual production phase. This digital iteration not only streamlines the creative process but also contributes to precision and efficiency in materializing furniture pieces.

Translating Designs into CNC Instructions

Once the digital design is ready, it’s transformed into CNC instructions, an essential step in the precision-driven process. These instructions act as a detailed roadmap for the CNC machine, guiding it through each step of the intricate process. From specifying cuts to outlining shapes, these instructions ensure that the CNC machine brings the digital design to life with meticulous accuracy. This seamless translation from virtual design to machine instructions is a pivotal stage, guaranteeing that the envisioned furniture piece is replicated with exact precision in the final product.

Achieving Intricate Designs and Details

The precision cutting and carving capabilities of CNC machines allow craftsmen to bring to life even the most complex and delicate design elements. By utilizing advanced technology, intricate patterns and details are crafted with meticulous accuracy, ensuring that every curve and contour in the design is faithfully reproduced. This level of precision not only enhances the aesthetic appeal of furniture but also opens up new dimensions of creativity in the pursuit of exquisite and finely detailed pieces.

Precision Cutting and Carving

A hallmark of CNC machining is its extraordinary ability to execute precision cutting and carving in furniture production. This advanced capability allows craftsmen to tackle complex designs with finesse, turning what was once challenging into a seamless process. CNC machines operate with unparalleled accuracy, ensuring that every cut is exact and every carve is intricately detailed. This precision not only elevates the visual appeal of furniture but also sets a new standard for craftsmanship, enabling the creation of pieces that captivate the eye with their intricate and flawless detailing

Crafting Complex Shapes and Patterns

CNC machining’s process extends to crafting intricate shapes and patterns, unleashing creativity in furniture design. Designers can push boundaries and create unique pieces with unparalleled intricacy, thanks to the precision and capabilities of CNC machines.

Accommodating Diverse Material Choices

Whether crafting intricate wooden designs with CNC routers or shaping precise metal components using CNC mills, these machines enhance creative possibilities. This adaptability ensures craftsmen can choose the best materials, contributing to the durability and aesthetics of the final furniture pieces. CNC machining stands as a pivotal technology in modern furniture production.

Woodworking with CNC Routers

In the realm of woodworking, CNC routers have become indispensable. These machines navigate through wood with precision, transforming raw lumber into finely crafted pieces. From traditional to avant-garde designs, the possibilities are limitless.

Metalworking with CNC Mills

The application of CNC machining extends seamlessly into metalworking through CNC mills. Crafting metal components with precision, these machines contribute to the creation of durable and precisely shaped elements for furniture production.

Precision and Quality Control

CNC machining guarantees meticulous precision and quality control in furniture production. By automating processes, these machines ensure consistent quality, minimize human error, and stand as a cornerstone for excellence in the industry.

Automated Processes for Repeatability

The inherent advantage of CNC machining lies in its automated processes, ensuring repeatability in every piece produced. This consistency becomes a cornerstone in maintaining stringent quality standards, vital in an era where precision is paramount.

Minimal Human Error Intervention

By minimizing human intervention, CNC machining significantly reduces the margin for error. The reliance on computer-guided precision translates into a reduction in imperfections, resulting in flawlessly crafted furniture pieces.

Achieving High-Quality Finishes

CNC machining excels in achieving high-quality finishes for furniture pieces. The process guarantees smooth surfaces and clean edges, contributing to the overall aesthetic appeal. The meticulous execution of each cut ensures precise detail reproduction, elevating the final product to meet the highest standards of craftsmanship and visual excellence.

Smooth Surfaces and Clean Edges

CNC machining guarantees not only precision in cuts but also high-quality finishes. The smooth surfaces and clean edges attained through this process contribute to the overall aesthetic appeal of the furniture, elevating it to a level of sophistication.

Precise Detail Reproduction

In the meticulous world of furniture design, details matter. CNC machining ensures that intricate details present in the digital design are faithfully reproduced in the final product. This attention to detail enhances the overall visual impact of the furniture.

Enhancing Durability and Strength

CNC machining contributes significantly to the durability and strength of furniture pieces. The precision in cutting and shaping ensures structurally sound constructions, providing furniture with robust integrity. The resulting pieces not only showcase intricate designs but also stand as enduring testaments to the marriage of technological precision and lasting quality in modern furniture production.

Structurally Sound Furniture Pieces

Beyond aesthetics, CNC machining contributes significantly to the structural soundness of furniture pieces. The precision in cutting and shaping results in items that not only look impressive but also stand robust against the tests of time.

Long-lasting Quality

The durability and strength achieved through CNC machining translate into long-lasting quality. Furniture becomes more than just visually appealing; it becomes a testament to craftsmanship, resilience, and enduring quality.

Applications of CNC Machining in Furniture Production

CNC machining revolutionizes furniture production by creating customized pieces for homes and businesses with unparalleled precision. It plays a crucial role in architectural woodworking and interior design, bringing intricate detailing to life. Additionally, the versatility of CNC machines extends to crafting specialty furniture, offering a wide range of possibilities for unique applications.

Custom Furniture for Homes and Businesses

The applications of CNC machining in furniture production extend far and wide. From crafting custom pieces for homes, tailored to individual tastes, to creating unique solutions for businesses seeking a distinct aesthetic, the versatility of CNC machining is on full display.

Architectural Woodworking and Interior Design

Architectural woodworking and interior design benefit immensely from the precision of CNC machining. Whether it’s the intricate detailing of architectural elements or the realization of bespoke interior designs, CNC machining proves to be an indispensable tool in achieving perfection.

Specialty Furniture for Unique Applications

The flexibility of CNC machining shines when it comes to crafting specialty furniture for unique applications. From one-of-a-kind statement pieces to furniture designed for specific needs, CNC machining unlocks a realm of possibilities that were once considered unattainable.

Conclusion

In conclusion, the integration of CNC machining in furniture production is a testament to human creativity and technological advancement converging harmoniously. As the industry continues to evolve, the marriage of precision and imagination facilitated by CNC machining will undoubtedly reach new heights. The future promises not only visually stunning and intricately designed furniture but also a seamless synthesis of craftsmanship and technology that defines the very essence of modern living. The revolution of precision in furniture production is underway, shaping the way we perceive and interact with the furniture that fills our living spaces.