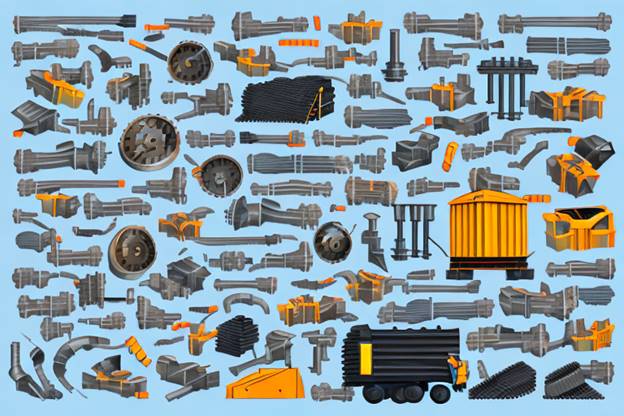

Mining is an essential industry that involves heavy-duty machines and equipment. To keep this machinery in optimum condition, it is imperative to use high-quality equipment parts. This article will guide you through the process of finding the right mining equipment parts for your operation, and how proper maintenance can prolong equipment lifespan and ensure safety and efficiency.

Understanding the Importance of Quality Mining Equipment Parts

Ensuring Safety and Efficiency

Mining is a dangerous and challenging industry, and safety should always be a top priority. Quality mining equipment parts are the foundation of safe and efficient mining operations. Using subpar or incompatible parts can cause equipment malfunctions, leading to accidents and injuries. This can not only harm your workers but also damage your equipment, resulting in costly repairs and replacements.

On the other hand, investing in high-quality equipment parts can help ensure that your machinery operates at peak performance. This can increase your workers’ safety and productivity and reduce the risk of accidents and injuries.

Reducing Downtime and Maintenance Costs

Equipment downtime can be costly for mining operations. It can result in lost production, reduced profits, and increased maintenance costs. When equipment breaks down, it not only disrupts your operations but also requires time and money to repair. This can lead to delays and missed deadlines, ultimately affecting your bottom line.

Investing in high-quality equipment parts can help prevent frequent breakdowns and prolong machinery life, ultimately saving you time and money. By using parts that are specifically designed for your equipment, you can reduce the risk of unexpected downtime and minimize the need for costly repairs.

Prolonging Equipment Lifespan

Mining equipment is a significant investment, and it’s essential to get the most out of it. By using durable and long-lasting equipment parts, you can increase the lifespan of your machinery. This can help you avoid premature replacements while getting the most out of your investment.

When you invest in high-quality equipment parts, you’re not only prolonging the lifespan of your machinery but also improving its performance. This can help you achieve higher levels of productivity and efficiency, ultimately increasing your profits and ensuring the success of your mining operation.

Identifying the Right Mining Equipment Parts for Your Operation

Mining equipment is a significant investment for any mining operation, and it is crucial to ensure that the machinery is running efficiently to maximize productivity and minimize downtime. One of the critical aspects of maintaining mining equipment is replacing worn-out or damaged parts. However, identifying the right parts can be a daunting task, especially for those new to the mining industry.

Assessing Your Equipment’s Specific Requirements

Before purchasing any equipment parts, it is essential to assess the specific requirements of your equipment. This includes considering the brand, model, and age of the machinery. Some parts may be compatible with a particular device, while others may not be suitable. It is crucial to consult the equipment manual or seek advice from a qualified technician to determine the right parts for your equipment.

Furthermore, it is essential to consider the working conditions of your mining operation. Some equipment parts may be more suitable for harsh environments, while others may be better suited for less demanding conditions. By assessing your equipment’s specific requirements, you can identify the right parts that will enhance the performance and longevity of your machinery.

Considering Compatibility and Interchangeability

Another vital factor to consider when purchasing mining equipment parts is compatibility and interchangeability. This refers to the ability of the parts to work interchangeably with other components of the equipment. It is crucial to ensure that the parts will work seamlessly together and not compromise the performance of the machinery.

Compatibility and interchangeability are essential when replacing critical components such as hydraulic pumps, engines, and transmissions. These parts must work together for the equipment to function correctly. It is essential to purchase parts from reputable suppliers who can guarantee compatibility and interchangeability.

Evaluating OEM vs. Aftermarket Parts

When purchasing equipment parts, you also have options between OEM and aftermarket parts. Original Equipment Manufacturer (OEM) parts are made by the equipment manufacturer while aftermarket parts are produced by third-party companies. Each has its advantages and disadvantages, and it is essential to evaluate which option is best suited for your operation.

OEM parts are typically more expensive than aftermarket parts, but they are designed specifically for the equipment and are guaranteed to work seamlessly with other components. OEM parts also come with a warranty, ensuring that you are protected against defects and malfunctions.

On the other hand, aftermarket parts are generally cheaper than OEM parts, making them an attractive option for those looking to save on costs. However, the quality of aftermarket parts can vary significantly, and there is a risk of compatibility issues and reduced performance. It is crucial to purchase aftermarket parts from reputable suppliers who can guarantee quality and compatibility.

Tips for Sourcing Reliable Mining Equipment Parts Suppliers

Researching Supplier Reputation and Experience

Researching the supplier’s reputation and experience is crucial to ensuring that you are purchasing quality equipment parts. You can read reviews online, ask for referrals or speak to other industry professionals to get an idea of the supplier’s reliability and experience.

Comparing Product Quality and Pricing

Another important consideration when selecting mining equipment parts suppliers is comparing product quality and pricing. You should review multiple suppliers and compare their pricing, as well as the quality and features of their products, to ensure that you make an informed decision.

Evaluating Customer Support and Warranty Policies

Lastly, it is crucial to evaluate the supplier’s customer support and warranty policies. It is important to select a supplier with excellent customer service and after-sales support. Additionally, it is essential to consider the warranty policies offered by the supplier to ensure you are getting the best value for your investment.

Proper Maintenance and Storage of Mining Equipment Parts

Implementing a Preventative Maintenance Schedule

Maintaining mining equipment parts is as important as buying the right quality parts. Proper maintenance can prevent costly equipment breakdowns and prolong their lifespan. One way to ensure equipment maintenance is by implementing a preventative maintenance schedule. This plan specifies the maintenance requirements and timing for each machine in operation.

Ensuring Proper Storage Conditions

Storing equipment parts correctly is essential to avoid contamination and damage. It is crucial to store parts in a dry, clean and suitable environment, free from dust, moisture and heat damage. You can use labeled storage containers to ensure parts are kept securely and organized.

Training Staff on Equipment Maintenance Best Practices

Ensuring your staff is well-trained in equipment maintenance best practices is a key factor in prolonging equipment lifespan. It is important to provide training on proper maintenance practices and techniques, including the correct use of equipment parts. This training can help prevent accidents, downtime, and unnecessary expenses.