In the competitive retail and consumer goods environment of today, a good bag is no longer just a functional vehicle, but also a statement of your brand. Every successful bag label has an undisclosed to the public manufacturer behind it that has the ability to take design concepts for a bag and transform them into quality products that appeal to end users. Among the manufacturers that have steadily appeared and grown in the industry for the last 15 years, two stood out the most: Meyzy, the China custom bag maker, highly regarded for its precision and versatility.

With an end-to-end, integrated process and over 16 years of experience in OEM/ ODM production, Meyzy caters to brands – whether new or established – designing their products from daily backpacks to high-end travel cases. In this article, we take a look at Meyzy capabilities, product range, quality ideology and what makes it special in the global bag industry.

The Evolution of Meyzy Bags: Crafting Identity Through Design

When talking about Meyzy bags, it’s essential to understand that they represent more than just products — they embody a philosophy of thoughtful design, manufacturing consistency, and adaptability to market trends. Founded in Qingdao, China, Meyzy initially focused on casual handbags and luggage, leveraging professional industry experience and a deep commitment to quality. Over the years, the business expanded from serving the Japanese market to supplying brands globally, including in North America, Europe, Southeast Asia, and beyond.

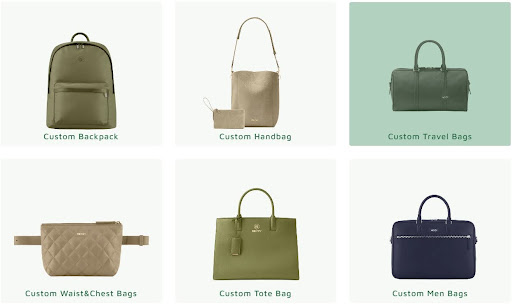

Now Meyzy’s line includes a wide variety of customizable bags — from fashion-forward totes and practical backpacks to travel-specific pieces and accessories. This development is indicative of the brand’s interpretation of the changing consumer needs, in terms of both form and function. In addition to stock designs, Meyzy partners with brands to hone ideas, select materials, and finalise structural details that help a product succeed commercially.

A Full-Spectrum OEM/ODM Process: Turning Concepts into Reality

Meyzy manufacturing is based on a true OEM/ODM model, which simply means the company not only manufactures bags but also works with the client from start to finish on the product lifecycle. Meyzy’s internal teams maintain nothing but the highest quality levels at every stage of the process from concept and design through prototyping, sampling, sourcing materials, manufacturing and final quality control to make sure that all stages meet the client’s expectations.

This level of integration provides several advantages:

- Rapid prototyping: Samples can be produced within as little as 7–15 days, allowing brands to evaluate design feasibility quickly.

- Customized material selection: A wide range of options — canvas, nylon, premium PU leathers, and certified sustainable textiles — lets brands tailor products based on target markets and price points.

- Dedicated quality checkpoints: Multiple inspection stages — from raw materials to final packing — ensure that the finished products meet or exceed industry standards.

Such a comprehensive manufacturing pipeline allows Meyzy to balance creativity, cost control, and production consistency — a rare combination in large-scale bag manufacturing.

Global Reach and Brand Partnerships

The growth of Meyzy is a representation of the deliberate targeting of foreign markets. With a solid foundation in Japan, the firm has gradually expanded its network to include retailers and private labels in such countries as Canada, the U.S., Australia, Singapore, Malaysia and in parts of Europe.

Instead of being a faceless factory, Meyzy presents itself as an ally for its clients. It’s for brands big and small — from mega-companies with stringent quality and delivery needs to emerging fashion labels that require flexible minimum order quantities and responsive sampling. This customer-focused approach has helped establish Meyzy as a trusted partner for brands looking for nimble production that doesn’t compromise on artistry.

Travel Bag Manufacturing Capabilities: Built for Performance and Brand Identity

One of Meyzy’s standout product lines lies in its travel bag manufacturing capabilities — an area where the company has developed robust expertise. Whether it’s duffel bags, weekenders, cabin-friendly carry-ons, or multifunctional totes, Meyzy offers end-to-end travel bag solutions tailored to different traveler needs.

These manufacturing capabilities extend beyond basic construction:

- Function-driven engineering: Bags are tested for balance, hardware resilience, reinforced stress points, and overall usability based on real travel scenarios.

- Customization options: Brands can specify fabrics, internal layouts, compartments, straps, and hardware, ensuring each travel bag aligns with its audience and price point.

- Compliance and certification: Materials and processes comply with international regulatory standards (e.g., REACH and EU safety benchmarks), helping brands sell confidently in regulated markets.

This combination of quality, flexibility, and design support makes Meyzy a competitive choice for brands looking to enter or expand within the travel and lifestyle segments.

Commitment to Quality and Sustainability

Quality at Meyzy is not just a catchphrase — it’s baked into every production decision. The company is subject to international standard audits such as ISO and BSCI, and the quality assurance is done with AQL (Acceptable Quality Level) standards to guarantee that each batch of performance is uniform.

Meyzy is also increasingly focused on green living. With GRS (Global Recycled Standard) and GOTS (Global Organic Textile Standard) certified fabric, sustainable sourcing is a key component in the development of products. The company is actively investigating new sustainable solutions – from recycled plastics to plant-based leathers – in light of changing regulatory and consumer demands.

Such dedication is appealing to global brands and retailers, which are running sustainability as a key part of their value prop.

Operational Efficiency and Logistics Support

An aspect of Meyzy’s way of operating is to be predictable. Brands need the quality to be consistent and delivery times to be predictable – particularly when they’re rolling-out seasonal collections or managing large-volume orders.

Meyzy values transparent milestones of production and logistics that enable them to meet delivery deadlines. Updates are transparent during sampling , production and shipping, keeping customers informed of the status of their orders and minimizing last minute surprises.

And the company’s scalable production capabilities and flexible minimum order quantities allow for both small-batch pilot runs and large-scale manufacturing projects, all under the same quality standards.

Conclusion: Why Meyzy Is a Strategic Partner for Modern Bag Brands

From its origins as a local-scale producer to its present global reach, Meyzy has always proved that good manufacturing practices would make the brand’s products stand out among the mass-produced commodity goods. With its full range of services -OEM/ODM, tailorable customisation services, focus on quality and sustainability, strong manufacturing capabilities for travel bags, and business opportunity for the factory- it is definitely a strong contender for any company looking for a factory partner in innovation, reliability, and design integrity.

Ultimately, what sets Meyzy apart isn’t just the bags it produces — it’s the way it bridges brand vision with real-world product performance, helping companies of every scale deliver products that look great, perform well, and communicate value to customers across the globe.